Product Overview

In cutting as well as non cutting metalworking processes, the coolant lubricants produce aerosols, mist and vapours that contaminate the air in production facilities and affect the health of the operators.

Under a license partnership with one of the leading companies from Germany in Air purification – AFS Air Filter Systeme GmbH – NAF offers powerful oil and mist filtration units to provide a clean working environment.

SPECIAL FEATURES

NAF oil mist collectors are professional solution for collecting and purifying air that has been contaminated by

- Oil and emulsion mist

- Minimum lubrication mist

And can be used as

- a compact single device for separating oil and emulsion mist from one mechining centre.

- a central or group exhaust system for separation of oil and emulsion mist from multiple machine tools in a production hall.

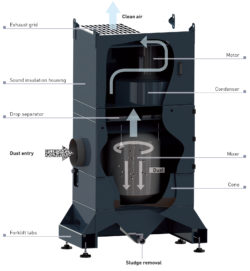

WORKING PRINCIPLE

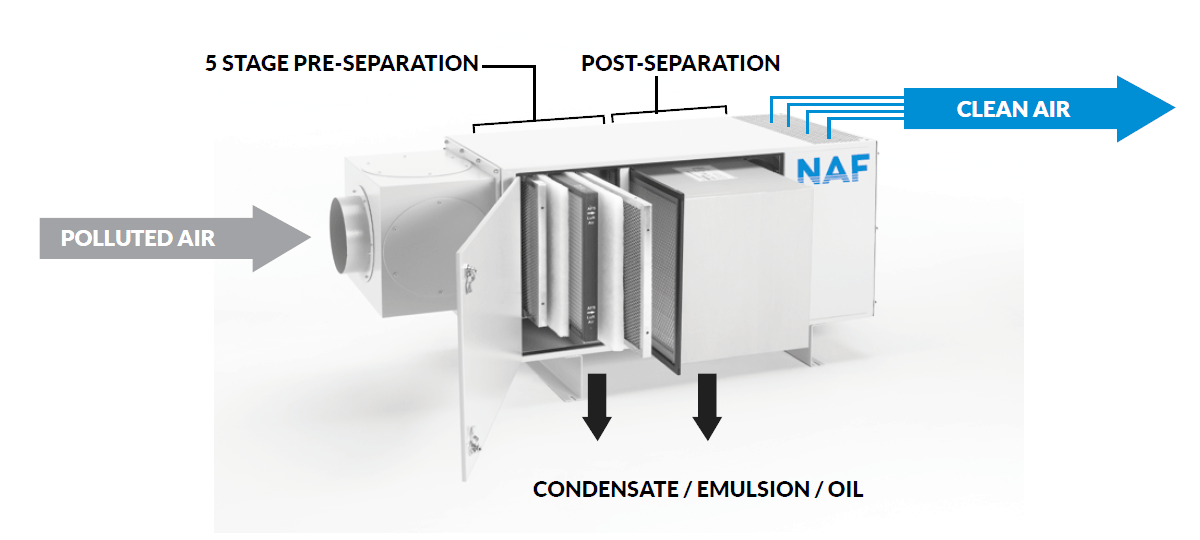

In comparison to conventional electrostatic precipitators or separators, NAF air purification devices work on the basis of a mechanical filtration and separation process that consist of a five stage pre separation in combination with a variable post-separation process which ensures a much higher filtration efficiency.

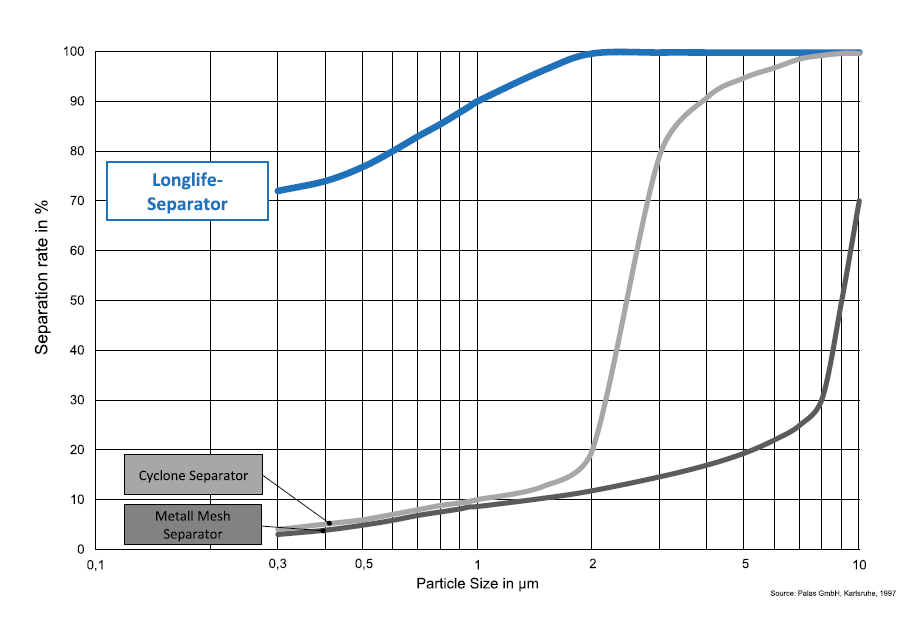

The pre-separation consists of an ideal adapted combination of metal mesh separators, filter fleeces, and, at its core, the long life separator. The post – separation consist of a H13 HEPA filter (separation rate > 99.95% based on partical size of 0.4μm). Because the preliminary separation is so extremely efficient, H13 filter can be used for a very long time..

THE LONGLIFE SEPARATOR

The heart of every OILEX air cleaning unit is the Longlife separator developed by AFS. This is a self-cleaning baffle plate separator, which ensures that all particles from a size of two thousandths of a millimeter (2.0 μm) are completely separated from the air stream. Independent studies confirm the high efficiency of the AFS technology.